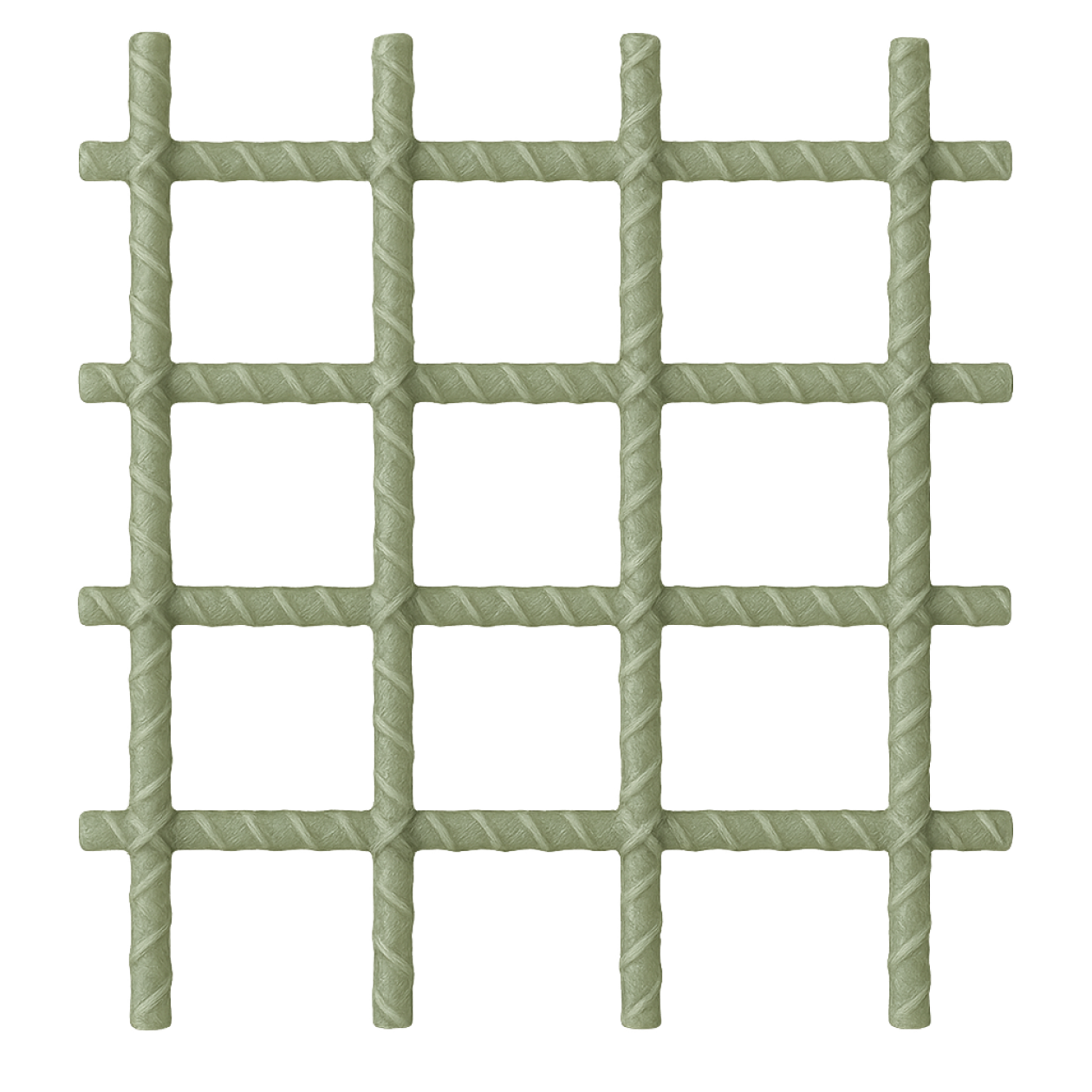

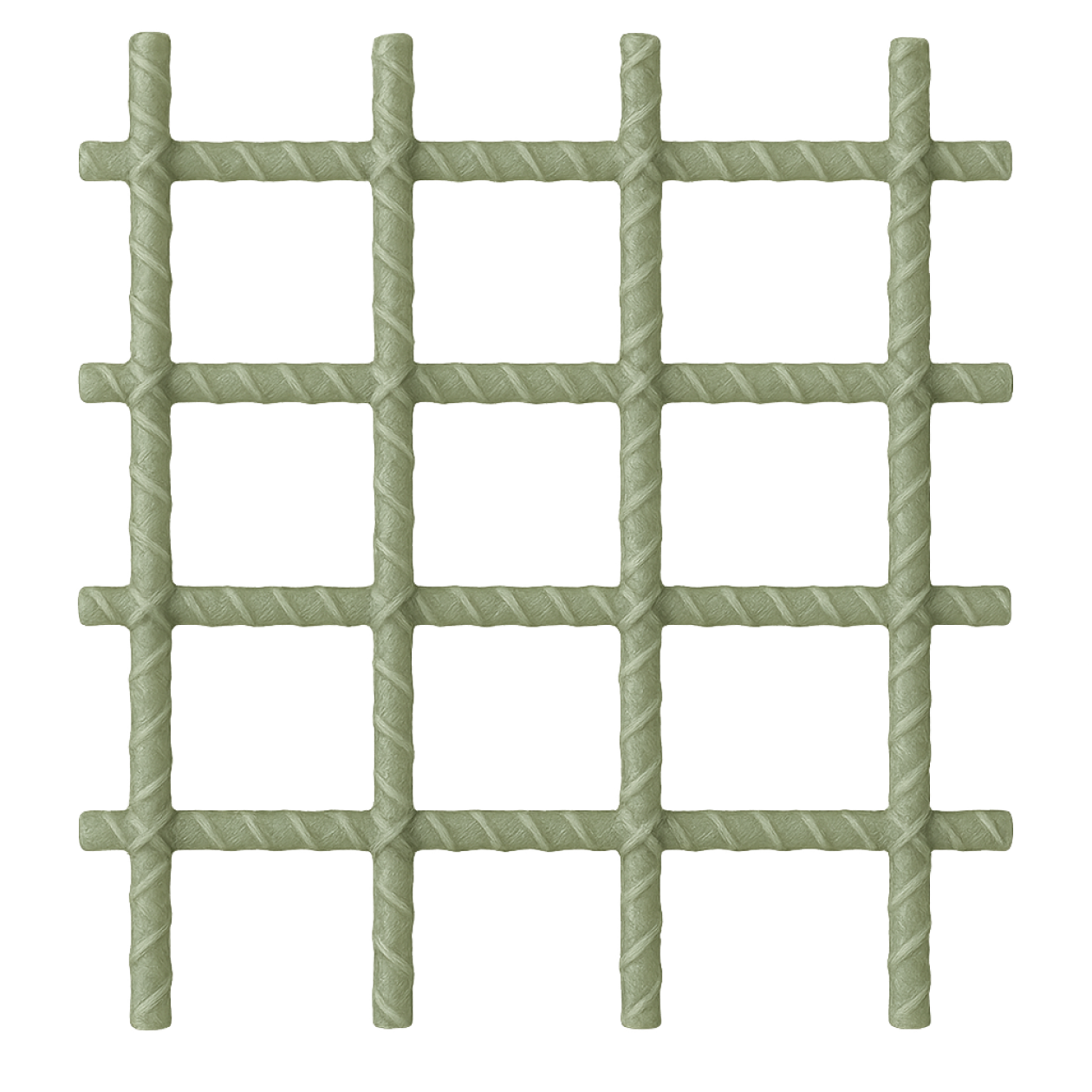

Advantages of using F+G Mesh

F+G mesh represents an evolution of steel mesh rebar and makes the F+G composite technology applicable in construction in practically every of its construction. Composite reinforcement mesh is sustainable and shows prevailing results. The use of FRP mesh in various construction projects not only enhances structural integrity but also opens new possibilities for innovative design and more efficient construction practices.